We specialize in manufacturing pneumatic marking machines. From the perspective of users, we continuously improve the quality of marking machines, through the effort of technical personnels, and the actual operation of marking machines in the workshops.

Chinancsk.com mainly focus on numerical machines and pneumatic machines including laser engraving machines,yag laser,cnc engraving with high quality but wholesale cheap price. shop engraving machinesonline now. Nachang pneumatic marking machines enjoy great popularity both at home and abroad for excellent quality. We can research and develop machines with independent intellectual property rights of patents, and our technology is in the leading position in the domestic market, having obtained CE certificate.

We have been implementing the production value of "product value and the best services are greater than product prices". "Striving for perfection" is our quality approach. Our business objective is "excellent quality, perfect program, and satisfying results".

If you are interested in our products, please contact us freely. We are looking forward to cooperating with potential customers from at home and abroad for mutual development.

Summary

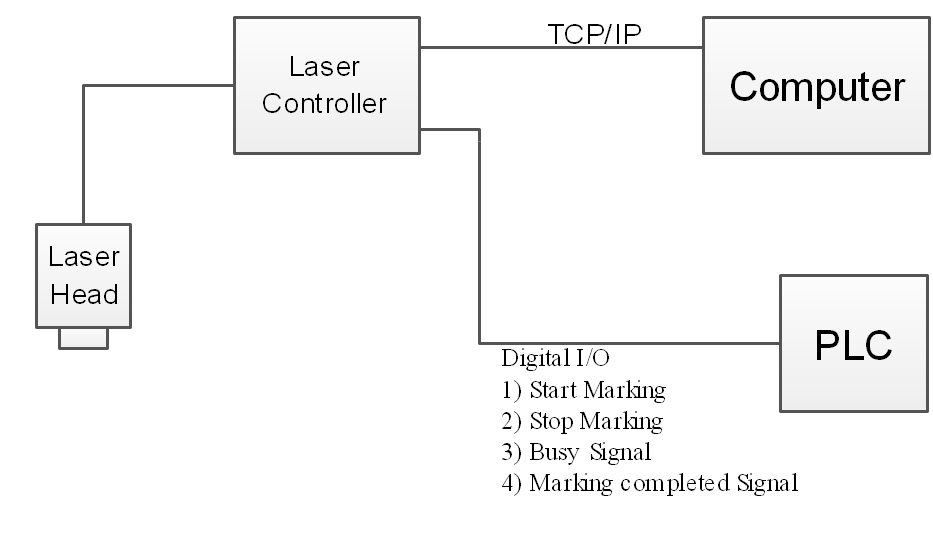

For automatic laser marking, NCSK designed customized laser marking machine which can connect with PLC。Custom function including:

1)Ethernet interface for remote data transmission

2)Extended I/O for PLC communication

3)Software Development Kit(SDK)

Figure 1-1 Automatic laser marking solution

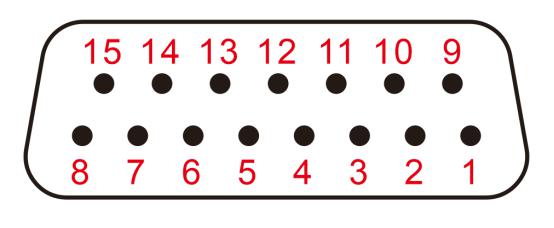

2. Extend I/O for PLC communication

PLC need control signal and state signal to control the laser marking machine. So we add these signals in an extended I/O. The extended I/O can be DB15 or DB25, depending on how many signals need to be used.

Figure 2-1 Laser Marking Machine Extended I/O for PLC control

2.1 General Input Signal

General Input Signals are use for controlling the working state of laser machine。Including:

1)Start Marking Signal:Machine start making when it’s active.

2)Stop Marking Signal:Machine stop marking when it’s active, and show warning information.

3)Safety Door Signal:Machine stop marking when it’s active.

4)File Select Signal:Use input signal to select the right file to marking。For example,INPUT[6:4] ”001” select file A to marking,INPUT[6:4] “010” select file B to marking。

Extended I/O support 8 general input signals,figure 2-2 shows the pin diagram:

Figure 2-2 Pin diagram of input signal

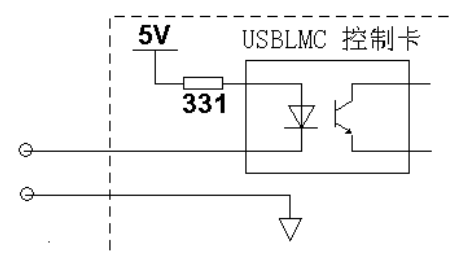

2.2 General Output Signal

General output signals show the working state of laser marking machine。

1)Busy Marking:Active when machine is marking

2)Finished Marking:Output an pulse signal when finished marking.

3)Red light indication signal:Active when Red light is indicating。

The output signal is TTL output by default. Short circuit or grounding should be avoided.

3. Software Development Kit (SDK)

NCSK also supply SDK for secondary development of software. With this SDK, you can integrate the core functions of laser marking software into your own program.

The SDK is suitable for Windows system environment and the development language is C++. Figure 3-1shows a demo program developed by this SDK.

Figure 3-1 demo program developed by SDK